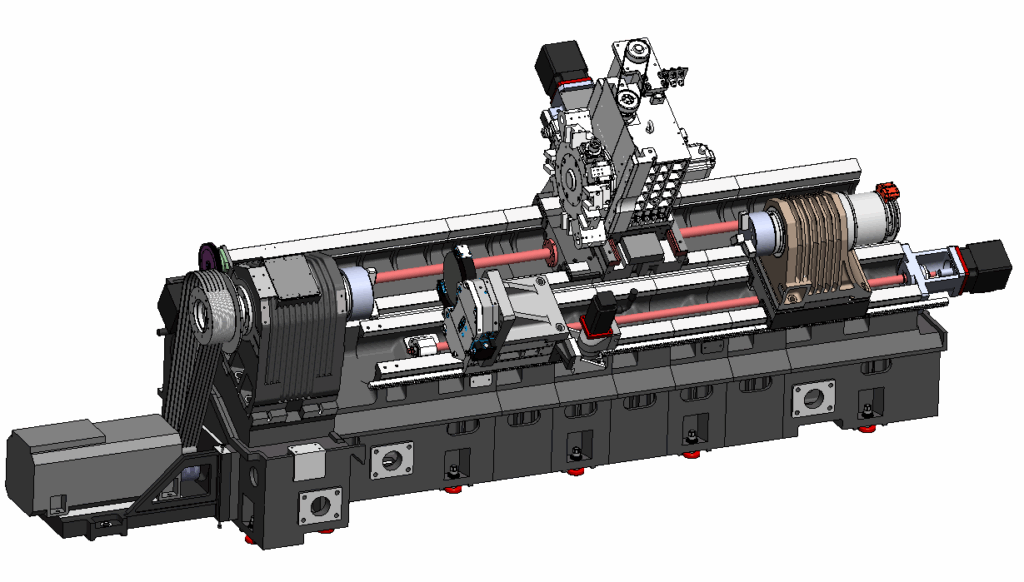

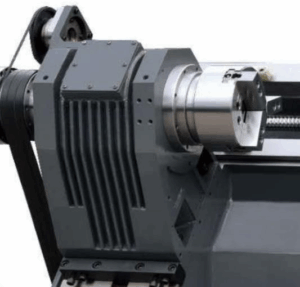

🌐 DUAL-SPINDLE CNC TURNING CENTER

Smarter, Faster, More Precise

🔧 Engineered for High-Volume, High-Precision Manufacturing

Our Dual-Spindle CNC Turning Center combines advanced design, cutting-edge performance, and automation-ready capabilities to streamline your turning operations. Whether you’re in automotive, aerospace, medical, or precision engineering, this machine delivers consistent, accurate results with optimized cycle times.

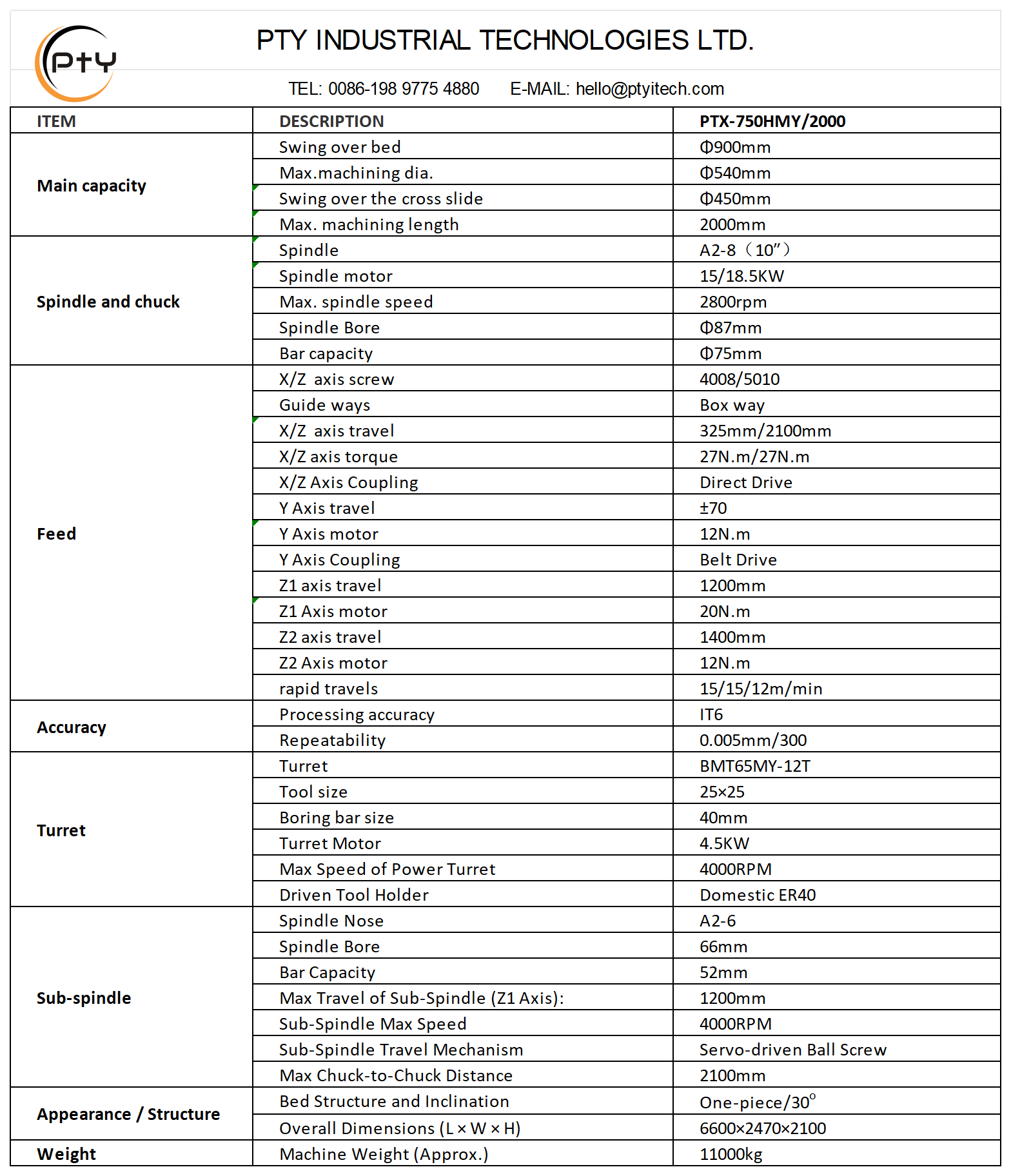

⚙️ Key Features at a Glance

✅ Dual-Spindle, Single-Turret (Optional Dual Turret)

Simultaneous operations or first/second process transfer in one setup. Perfect for reducing cycle time and increasing throughput.

✅ Compact Footprint, Maximum Productivity

Smaller footprint compared to two single-spindle machines. Ideal for space-constrained production environments.

✅ High-Rigidity HT300 Slant-Bed Construction

One-piece cast iron body with 30° inclined structure ensures long-term stability, vibration resistance, and machining precision.

✅ High-Speed Built-In Spindles (Up to 2800 rpm)

Integrated electric spindle system provides excellent thermal stability, ideal for precision turning and fine surface finishing.

✅ Box-Way Guideways + Enclosed X-Axis

Superior damping and protection design prolong tool life and machine serviceability.

✅ Automation Integration

Compatible with bar feeders, part catchers, Supports full-process machining from raw to finished part.

✅ Y-Axis Live Tooling (Optional)

Enables turn-mill operations, multi-axis machining, and greater process flexibility.

✅ Intelligent Maintenance

Automatic lubrication, visual status monitoring, and chip removal system reduce downtime and ensure reliability.

🏭 Applications

Automotive Parts (shafts, bushings, flanges)

Medical Components (implants, surgical tools)

Aerospace Fittings (tubes, connectors)

Precision Engineering (electronic housings, custom fasteners)

🚀 Your Competitive Edge in Smart Manufacturing

Reduce operator dependency

Shorten cycle time

Minimize work-in-progress

Scale with confidence

📩 Contact Us Today

Looking to expand your smart production line?

Let’s talk: hello@ptyitech.com or +86 198 9775 4880

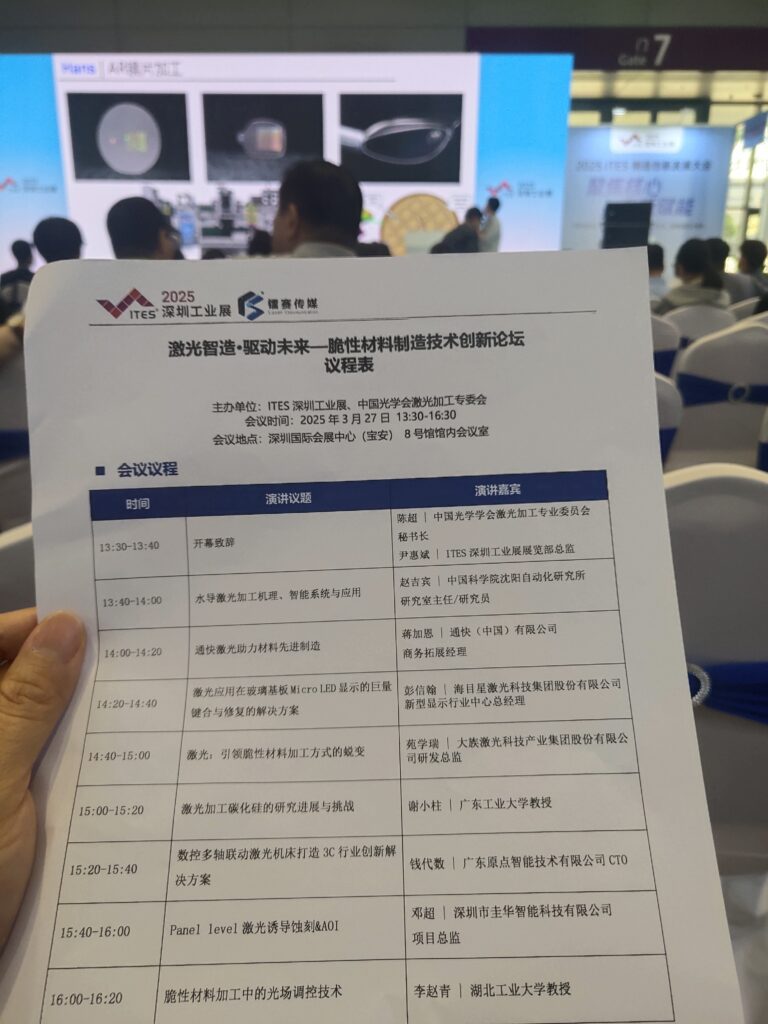

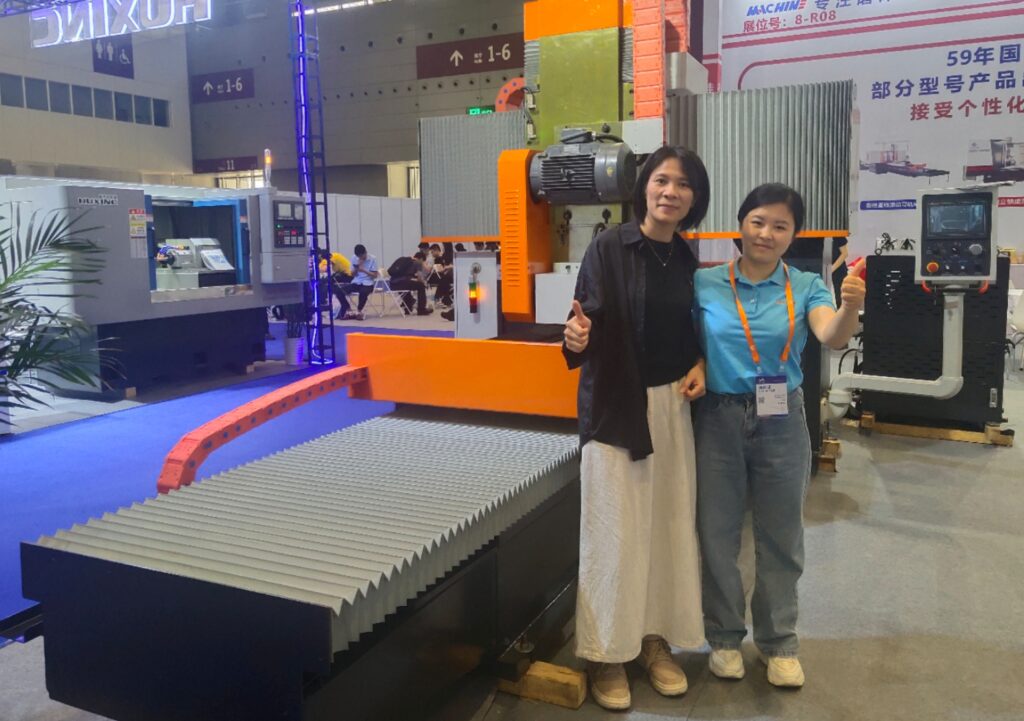

At the exhibition, I not only gained insights into the latest developments in industrial automation but also unexpectedly met several colleagues I hadn’t seen in years. We reminisced about the industry’s evolution, discussed future directions, and shared valuable experiences in automation.

At the exhibition, I not only gained insights into the latest developments in industrial automation but also unexpectedly met several colleagues I hadn’t seen in years. We reminisced about the industry’s evolution, discussed future directions, and shared valuable experiences in automation.