A practical CNC machine selection guide covering 3-axis, 4-axis, 3+2, and 5-axis machining. Learn how to choose the right CNC machine based on part geometry, tolerance, and production requirements.

CNC Machine Tool Selection Guide

How to Choose the Right CNC Machine for Any Part

Introduction

Selecting the right CNC machine tool is a critical decision in manufacturing.

However, many companies still choose machines based on brand, axis count, or price, rather than actual part requirements.

This guide provides a part-driven CNC machine selection methodology, covering:

- 3-axis, 4-axis, 3+2, and 5-axis CNC machining

- Turning, milling, and multi-task machining

- Practical decision logic used by manufacturing engineers

The goal is simple: match the machine to the part, not the other way around.

Key Factors in CNC Machine Selection

Before choosing a CNC machine, always evaluate the following five factors:

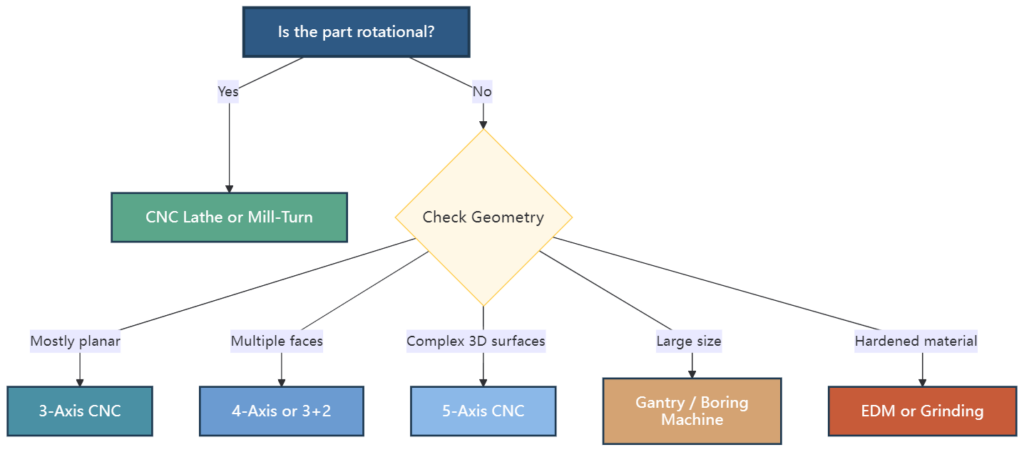

Part Geometry

Is the part rotational, prismatic, or free-form?

- Rotational → CNC lathe or mill-turn

- Prismatic → Machining center

- Free-form → 5-axis machining

Machining Features

Common features include:

- Holes, slots, pockets

- Angled faces

- Free-form surfaces

These features determine whether 3-axis, 4-axis, or 5-axis machining is required.

Tolerance and Surface Finish

- Standard tolerance (±0.05 mm): most CNC machines

- Tight tolerance (±0.005 mm): higher rigidity, better control system

- Complex surfaces: require continuous tool orientation control

Production Volume

- Prototype / small batch → flexible CNC machines

- Medium batch → 3+2 or horizontal machining

- Mass production → automation, fixtures, dedicated machines

Material and Part Size

- Aluminum → high-speed machining

- Steel / hardened steel → rigidity and torque

- Large parts → gantry or horizontal machines

CNC Machining Processes and Machine Types

| Machining Process | CNC Machine Type | Typical Applications |

|---|---|---|

| Turning | CNC Lathe | Shafts, flanges, sleeves |

| Milling | Vertical / Horizontal Machining Center | Plates, housings |

| Drilling & Tapping | Tapping Center | Aluminum parts |

| Boring | Horizontal Boring Mill | Gearboxes |

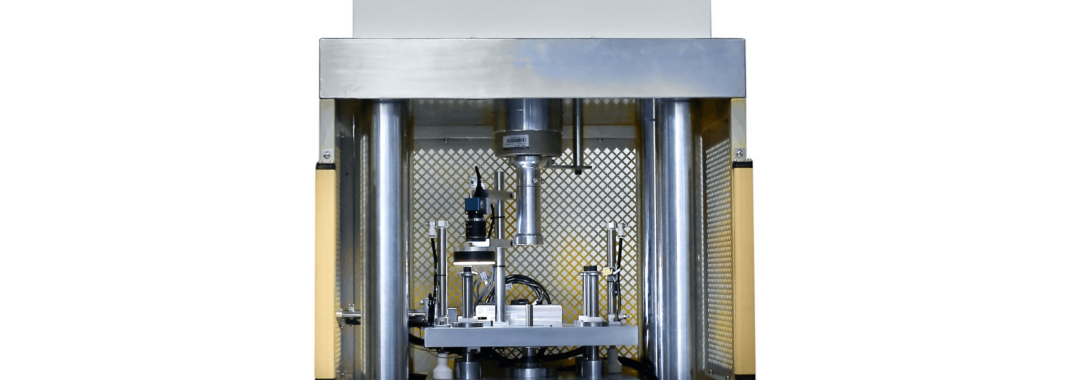

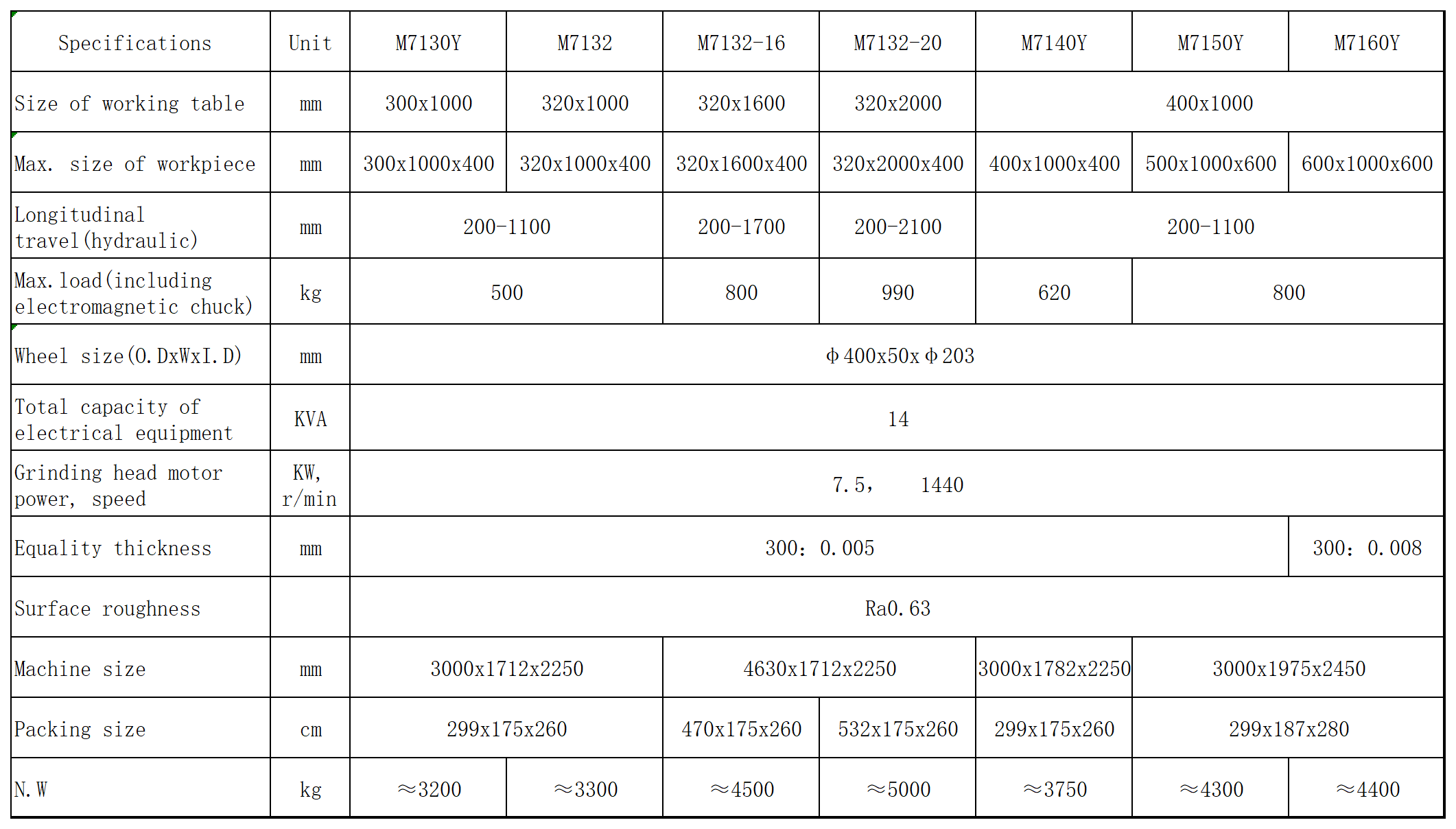

| Grinding | Surface / Cylindrical Grinder | High-precision parts |

| EDM / Wire EDM | EDM / WEDM | Hardened steel |

| Multi-task Machining | Mill-Turn Center | Complex components |

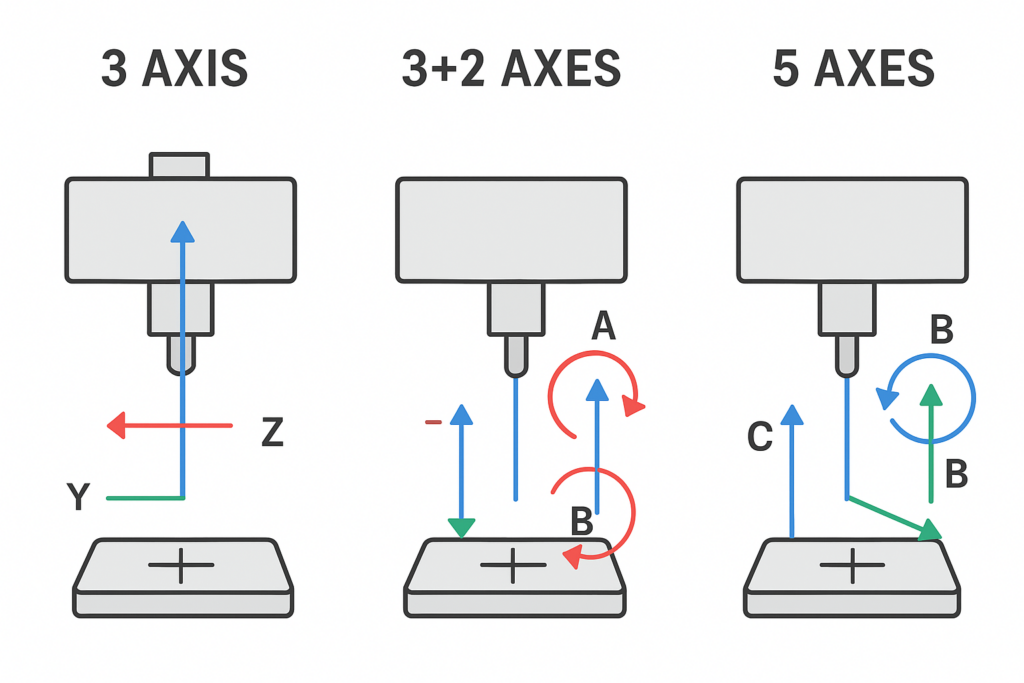

CNC Machine Selection by Axis Configuration

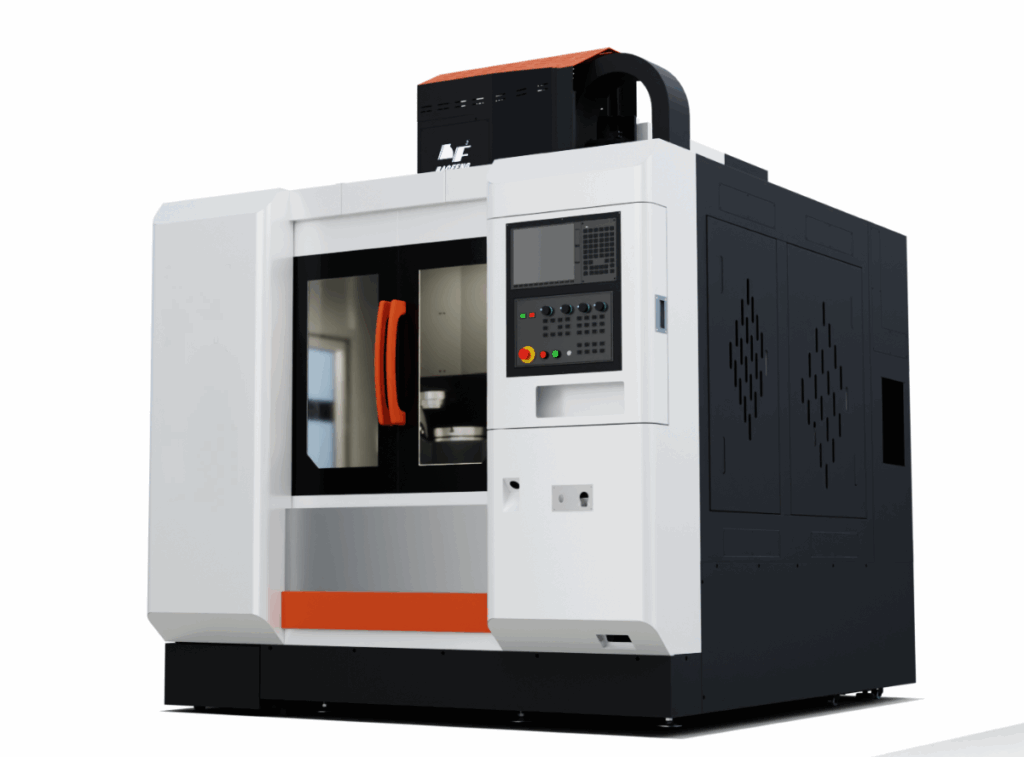

3-Axis CNC Machining Center

- X / Y / Z linear axes

- Best for planar and 2.5D machining

- Lowest cost and highest versatility

Typical applications: brackets, plates, general mechanical parts

4-Axis CNC Machining Center

- Adds one rotary axis (A or C)

- Enables indexed side machining

- Reduces re-clamping

Typical applications: parts with side holes or indexed features

3+2 Axis CNC Machining (Positional 5-Axis)

- Rotary axes used for positioning only

- Machining still performed in X/Y/Z

Advantages:

- One setup for multiple faces

- Higher accuracy than 3-axis

- Lower cost than full 5-axis machining

Typical 5-Axis CNC machine applications: housings, stamping parts, multi-face components

5-Axis Simultaneous CNC Machining

- Continuous interpolation of linear and rotary axes

- Full control of tool orientation

Required for:

- Complex 3D surfaces

- Molds, impellers, turbine blades

Gantry CNC Machining Centers

- Large work envelope

- High rigidity

Typical applications: large molds and structural components

Mill-Turn (Multi-Task) CNC Machines

- Turning and milling in one setup

- Reduced handling and positioning error

Typical applications: complex rotational parts

How to Choose a CNC Machine by Part Type

| Part Type | Recommended CNC Machine | Axis Configuration |

|---|---|---|

| Shafts | CNC Lathe / Mill-Turn | 2–5 |

| Plates | 3-Axis Machining Center | 3 |

| Housings | Horizontal MC / 3+2 | 3+2 |

| Stamping Parts (post-machining) | Five-Sided Machining Center | 3+2 |

| Molds | 5-Axis CNC Machine | 5 |

| Impellers | 5-Axis CNC Machine | 5 |

| Large Structures | Gantry CNC Machine | 3–5 |

| Hardened Inserts | EDM / Grinding | — |

CNC Machine Tool Selection Guide Tree

Common CNC Machine Selection Mistakes

Choosing Too Many Axes

More axes increase cost, complexity, and setup time.

Choose only what the part actually needs.

Selecting Machines by Brand Only

A famous CNC control system does not automatically guarantee better productivity.

Overusing 3-Axis Machining

Excessive re-clamping increases error and reduces efficiency.

Ignoring Total Manufacturing Cost

The right machine reduces fixtures, setups, and inspection time.