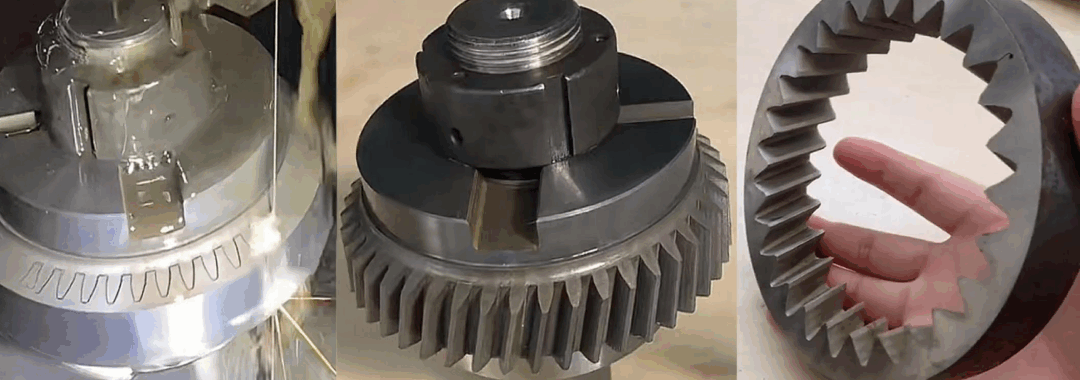

Case Study: Finding the Right WEDM Machine Within Budget

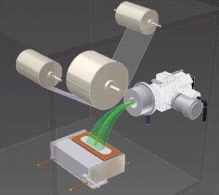

A client approached us for a new Wire EDM for mold manufacturing. After analyzing their requirements and budget, we found the target price was below high-end equipment levels, but sufficient for a reliable standard machine, without Wire EDM automatic wire threading.

We provided three tailored solutions:

- Option 1: Matched the target budget with upgraded configuration and performance.

- Option 2: Below budget with standard requirements .

- Option 3: Lower cost, with basic functionality.

The client ultimately chose Option 1, achieving the best balance between cost, capability, and long-term value.

Reflection: Building Trust Through Transparent Solutions

Why Budget Transparency Matters?

In machine sourcing, budget defines which suppliers to talk to, how to balance configuration vs. cost, and what level of risk or reliability the client can afford.

It’s not a limitation — it’s the starting point of smart sourcing.

we believe in showing clear, side-by-side options that reveal real value differences.

This transparent approach helps clients make informed decisions, strengthens trust, and proves our commitment to smart sourcing, not just selling.