6 Steps to Ensure Optimal Industrial Equipment Sourcing & Selection

We help overseas buyers make confident, technically sound decisions when sourcing industrial equipment from China — including, but not limited to, CNC machine tools. Our role is not to sell a specific brand, but to reduce uncertainty, eliminate mismatches, and ensure the machine you purchase is fit for your application, budget, and long‑term operation.

Our equipment sourcing support covers the entire decision and execution process — from early feasibility checks to final factory validation.

1. Clarifying Your Real Requirements when Equipment Sourcing

Regardless of equipment type, most sourcing failures originate from unclear or incomplete technical requirements.

Many machine sourcing problems start with incomplete or inaccurate specifications. We work with you to translate production goals into clear, engineering‑level requirements, including:

Part drawings and key tolerances

Material types and machining characteristics

Accuracy, rigidity, and thermal stability needs

Batch size, cycle time, and automation expectations

Power supply, footprint, and site constraints

This step prevents over‑specification, under‑specification, and costly mid‑project changes.

2. Equipment Selection & Technical Matching

Based on your clarified requirements, we perform application‑driven equipment selection, focusing on real operating performance rather than brochure parameters.

We evaluate and compare:

Structural design and rigidity

Core functional units and performance envelopes

Control systems, software, and automation interfaces

Component quality and supply chain stability

Long‑term reliability, serviceability, and maintenance considerations

The output is a shortlist of technically suitable equipment configurations, not a generic recommendation.

3. Manufacturer Screening & Factory Verification

Not all China machine manufacturers operate at the same engineering or quality level, even if specifications look similar.

We help you:

Filter out trading companies and unstable suppliers

Identify manufacturers with proven experience in your machine category

Verify real production capacity and quality control systems

Assess component sourcing (castings, guideways, spindles, control systems)

When required, this includes on‑site factory audits and build‑process verification.

4. Configuration Review & Risk Control

Before order confirmation, we conduct a technical configuration review to reduce delivery and performance risks.

Typical checks include:

Option necessity vs. cost impact

Compatibility between control system and hardware

Electrical, safety, and export compliance

Spare parts strategy and documentation completeness

This step helps avoid hidden cost increases and post‑delivery disputes.

5. Production Follow‑up & Acceptance Support

During manufacturing, we can assist with:

Build progress tracking

Key assembly and alignment checkpoints

Pre‑shipment inspection (PSI) coordination

Acceptance testing criteria definition

Our focus is ensuring the delivered machine matches the agreed technical scope — not just that it ships on time.

6. One Point of Technical Communication

We act as a technical interface between you and Chinese manufacturers.

This reduces:

Misinterpretation of drawings and specifications

Language‑driven technical errors

Delays caused by unclear responsibility

You communicate requirements once; we ensure they are correctly implemented.

Who This Service Is For

Our approach is best suited for:

Overseas manufacturers purchasing CNC machines from China

Engineering‑driven buyers who need technical validation

Distributors or integrators evaluating new suppliers

Buyers with limited local support in China

6 Representative Equipment Categories

Explore how we help clients optimize machine sourcing, coating line solutions, and spare parts quality.

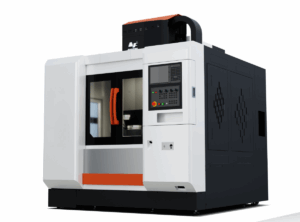

🔧 CNC Machine sourcing for parts with helicoid grooves

A South American customer needed to process a workpiece with multiple Helical Groove. The key to the processing was to feed along the axial direction while rotating to form a precise spiral path.a 4-axis vertical machine center was selected.

- Process Analysis

- CNC four/five -axis machining center,Composite milling and turning center comparison

- Existing capacity and cost consideration

⚙️ Wire cutting Machine Sourcing Within Budget

The client wanted a new EDM machine within a target budget. We presented three tailored solutions balancing cost, configuration, and performance, enabling the client to achieve the best value.

- Three-tier solution comparison

- Transparent decision-making

- Performance-cost optimization

🏭 Metallizer Project

For a large-scale coating line project, we coordinated with multiple metallizer manufacturers and conducted on-site evaluations. Three customized solutions were presented, each with clear trade-offs between cost and performance.

- Multi-factory coordination

- On-site capability assessment

- Tiered proposal strategy

🔧 Spare Parts Quality Issue

A European client experienced frequent machine breakdowns due to poor-quality spare parts. After coordinating multiple suppliers and conducting on-site validation, we identified design mismatches and implemented a reliable solution.

- Multi-supplier coordination

- On-site inspection and validation

- Root cause analysis

⚙️ Griding Machine Sourcing Within Budget

An impoter looking for good Quality griding machine within a tight target budget. They bought some before but was not satisfied with the quality.

- Choose manufacturers with high cost performance in the industry

- Conduct on-site investigations(taking into account geographical convenience).

- Continuously monitoring The production process until successful delivery.

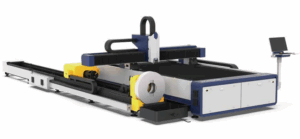

🏭 Brittle Material Laser Cutting Machine Sourcing

The customer needs to drill holes of various diameters in glass and is looking for a Laser Glass Cutting Machine for high cutting accuracy, fast speed, good Glass Edge Quality.

- Laser selection: UV / Green Laser Glass Cutting; Ultrafast Laser Cutting (Glass) / Femtosecond / Picosecond Laser Glass Cutting

- Comparison of solutions from multiple suppliers

- Determine the plan and track production to ensure smooth delivery.