CNC Machine Selection & Sourcing Guide

Choosing the right CNC machine is not just about specifications or price.

For manufacturers, integrators, and industrial buyers, CNC machine selection is a technical decision with long-term operational and financial impact.

This guide provides a structured framework to help you evaluate CNC machines objectively, avoid common sourcing mistakes, and make decisions aligned with your actual application requirements.

Why CNC Machine Selection Is Often Done Wrong

Many CNC sourcing projects fail to deliver expected results, not because of poor machines, but because of incorrect selection logic.

Common issues include:

- Selecting machines based purely on price or brand

- Over-specifying features that are never used

- Ignoring application-specific constraints

- Relying on incomplete or biased supplier information

- Underestimating long-term service and integration risks

A correct CNC decision starts with engineering logic, not marketing claims.

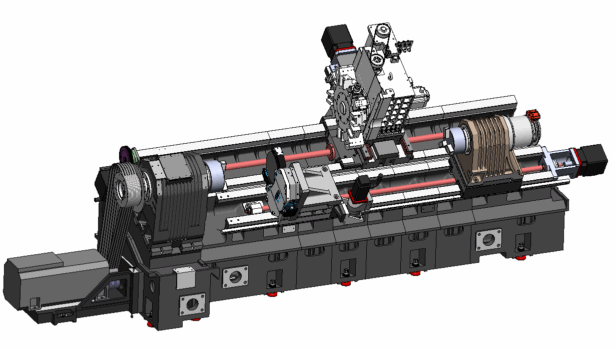

Main Types of CNC Machines

Understanding CNC machine categories helps narrow down options before technical comparison begins.

CNC Turning Centers

CNC turning centers are primarily used for rotational parts such as shafts, bushings, and cylindrical components.

Key considerations include spindle configuration, rigidity, tooling system, and automation readiness.

(Internal link: CNC Turning Center Selection Guide – future page)

CNC Machining Centers (Vertical & Horizontal)

Machining centers are designed for milling, drilling, and complex multi-surface machining.

The choice between vertical and horizontal configurations depends on part geometry, batch size, and chip evacuation requirements.

(Internal link: CNC Machining Center Selection Guide – future page)

Multi-Axis CNC Machines

Multi-axis CNC machines enable complex geometry machining and reduced setup time.

However, higher axis count does not automatically mean better productivity or accuracy for every application.

Special-Purpose CNC Equipment

Customized or application-specific CNC machines are often required for non-standard processes.

These projects demand higher emphasis on engineering validation and supplier capability assessment.

Key Technical Factors in CNC Machine Selection

A CNC machine should always be evaluated as a system, not as a collection of isolated specifications.

Application and Material Requirements

The machining process defines the machine — not the other way around.

Key questions include:

- What materials are being processed?

- What tolerances are functionally required?

- What is the production rhythm: prototype, small batch, or mass production?

Application clarity prevents unnecessary over-investment and under-performance.

Machine Structure and Mechanical Design

Structural design directly impacts accuracy retention and long-term stability.

Important aspects include:

- Bed structure and rigidity

- Guideway configuration

- Thermal stability design

- Load-bearing and vibration control

Machine structure quality often matters more than nominal accuracy values.

CNC Control System and Smart Features

The CNC control system defines usability, flexibility, and integration potential.

Evaluation should focus on:

- System stability and ecosystem maturity

- Compatibility with automation and MES systems

- Programming flexibility and operator learning curve

- Long-term availability of technical support

Smart functions add value only when aligned with real production needs.

Automation and Future Expansion

Automation readiness should be evaluated from the beginning, even if not implemented immediately.

Consider:

- Space and interface for automation

- Control system scalability

- Electrical and mechanical integration capacity

Planning ahead reduces costly retrofits later.

In-Depth Technical Analysis: Smart CNC Selection (Case Reference)

For buyers who require a deeper technical evaluation beyond basic selection criteria, we have prepared a dedicated technical analysis article.

This article explains how application requirements, machine structure, control system configuration, and long-term reliability should be evaluated together — rather than selecting a CNC machine based on isolated parameters.

👉 Read the full technical analysis:

Smart CNC Machine Selection – Technical Analysis Service

CNC Machine Sourcing Considerations

Selecting the right CNC machine does not automatically mean selecting the right supplier.

Key sourcing factors include:

- Manufacturer versus trading company transparency

- Engineering and customization capability

- Quality control and validation process

- Track record in similar applications

- After-sales and long-term service support

Technical correctness and supply chain reliability must be evaluated together.

Common CNC Sourcing Mistakes We See

Through real-world sourcing projects, several recurring issues stand out:

- Purchasing machines with excessive specifications that do not improve output

- Selecting unsuitable machine structures for the actual process

- Underestimating commissioning, training, and support requirements

- Relying on incomplete factory verification

Avoiding these mistakes often saves more cost than negotiating the initial price.

How PTY Helps with CNC Machine Selection

We support CNC sourcing projects with an independent, application-driven approach.

Our support typically includes:

- Technical requirement clarification

- Independent machine configuration evaluation

- Supplier and factory capability verification

- Cost versus performance assessment

- Risk identification before purchase decisions

Our role is to help you make technically sound and commercially rational decisions.

👉 Learn how we help with CNC sourcing

👉 Discuss your CNC application with an engineer

CNC Machine Selection FAQs

How do I know if a CNC machine is over-specified?

If features do not directly improve accuracy, productivity, or reliability for your application, they are likely unnecessary.

Is a higher-priced CNC machine always better?

Price often reflects configuration and brand positioning, not guaranteed suitability.

Can one CNC machine handle multiple applications?

In some cases yes, but compromises are common. Application prioritization is essential.

Final Note

A CNC machine is a long-term production asset.

A structured selection process reduces risk, controls cost, and improves operational outcomes.

If you are planning a CNC investment or reassessing an existing sourcing decision, a systematic evaluation is the most reliable starting point.